Company news,Industry news & FAQ

NEWS

PRODUCTS SEARCH

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

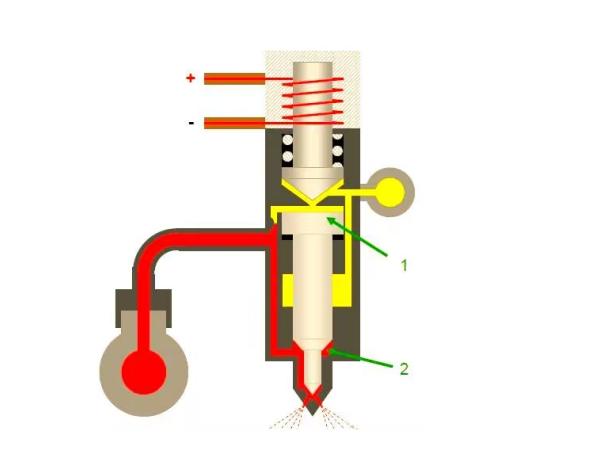

The fuel injector is an important component of the engine fuel supply system, which precisely controls the injection quantity, injection time, and injection pressure of fuel according to the operating requirements of the engine. Its working principle can be summarized as follows: when the engine control system sends an injection signal, the driving components such as solenoid valves or piezoelectric crystals inside the injector will quickly respond, causing fuel to be sprayed out of the nozzle at high speed, forming a mixture of misty fuel and air, and then entering the engine combustion chamber for combustion. By precisely controlling the fuel injection quantity, injection time, and injection pressure of the fuel injector, the engine can achieve the required power and fuel economy.

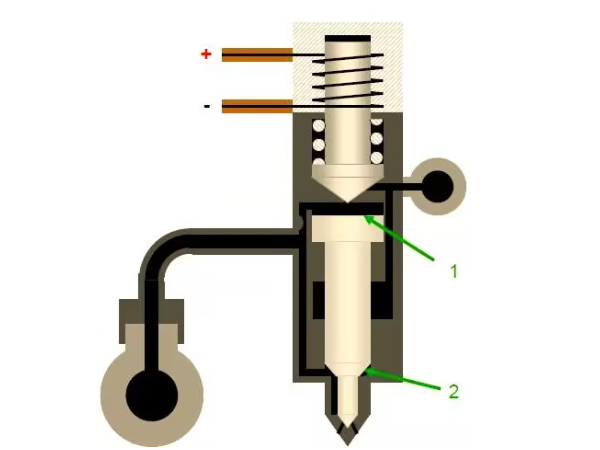

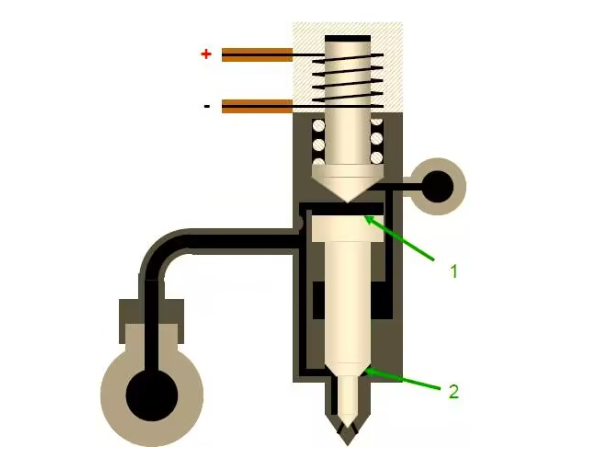

During the operation of the fuel injector, when the solenoid valve is not powered, the spring will push the solenoid valve core to remain closed. At this point, the top surface of the plunger and the protrusion area of the needle valve will be subjected to the same fuel pressure. Due to the large force area on the top surface of the plunger, it generates a downward force that is strong enough to maintain the injector needle valve in its closed position.

In the normal working state of the fuel injector, when the solenoid valve is not powered, the spring will continue to push the solenoid valve core to keep it in the closed state. At this point, the fuel pressure acting on the top surface of the plunger and the protrusion area of the needle valve is equal. Due to the large force area on the top surface of the plunger, it generates a significant downward force that is strong enough to ensure that the injector needle valve remains in the closed position at all times.

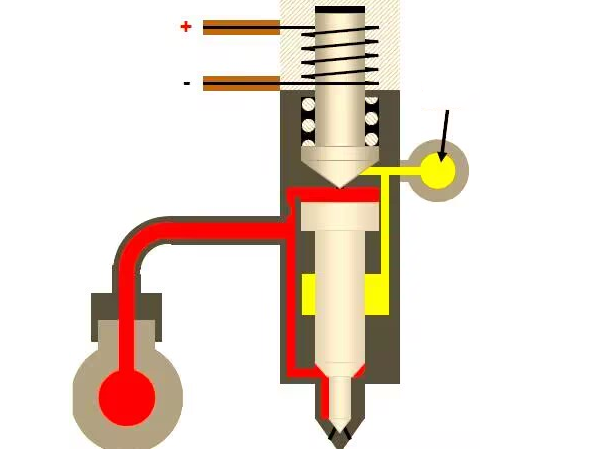

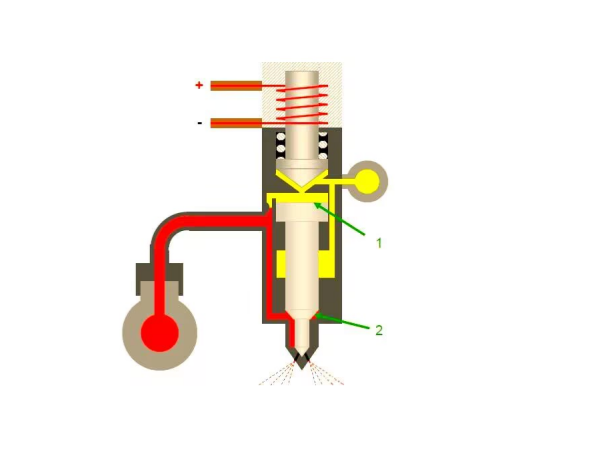

When the ECM sends a voltage signal to the solenoid valve to initiate the process of fuel injection into the cylinder, the solenoid valve generates an upward electromagnetic force. This electromagnetic force overcomes the resistance of the solenoid valve spring and pushes the iron core upwards. As the iron core rises, the oil leakage channel inside the injector is opened, preparing for the injection of fuel.

Under ECM control, the solenoid valve initiates the process of fuel injection into the cylinder through a voltage signal. During this process, the upward electromagnetic force generated by the solenoid valve exceeds the resistance of the spring, causing the iron core to rise. As the iron core rises, the oil leakage channel inside the injector is opened, laying the foundation for smooth fuel injection.

As the oil discharge channel opens, the pressure on the top surface of the plunger gradually decreases. This causes the pressure acting on the protrusion of the needle valve to exceed the pressure on the top surface of the plunger, thereby pushing the needle valve up from its self closing position. Subsequently, the fuel is forcefully injected into the cylinder through the nozzle holes at the head of the nozzle.

When the ECM determines that fuel injection is not currently required, it will cut off the power supply to the injector solenoid valve. Subsequently, the electromagnetic force disappeared, causing the solenoid valve core to return to the closed state under the action of the spring, thereby closing the oil discharge channel. At this point, the pressure on the top surface of the plunger begins to rise, pushing the plunger and needle valve assembly to reset, thus ending the fuel injection. At the same time, this pressure change causes the same fuel pressure to act again on the top surface of the plunger and the needle valve protrusion. Due to the larger force area on the top surface of the plunger, a greater downward force is generated, ensuring that the injector needle valve can be firmly held in the closed position until the ECM issues the next fuel injection command.

For high-pressure common rail fuel systems, maintaining cleanliness of the fuel system is crucial. Once the small passages inside the fuel injector are contaminated with particulate matter, it will seriously affect the smooth flow of fuel. If the pollution particles block the small passage leading to the top control room of the pillar race, the fuel injector may not be able to close properly, resulting in continuous fuel injection. This situation will result in ineffective control of the amount of fuel injected into the cylinder, which may lead to serious engine malfunctions.

English

English Русский

Русский Español

Español