PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

New Product CR777 Diesel Test Bench Common Rail Injector Calibration Machine

0086-18253885135

1. Use Instructions

1) Before using the CR777 common rail injector testing table, please read this manual carefully.

2) This manual is written according to the existing function and product configuration of the product. If new functions and configurations are added, this manual will be modified. The company has the right to modify the instructions without notifying you in advance.

3) Please read the "precautions" and "use instructions" of the instruction manual to ensure that you can test safely and correctly.

2. Precautions For The Protection And Use Of The Trial Table Of Common Rail Injector

1) The operator must operate in accordance with the maintenance safety rules of the oil pump repair industry and related diesel electrical control systems. Pay special attention to environmental factors such as the surrounding acid, alkali, gas, high -pressure heavy objects, and items that are prone to sparks to prevent damage to equipment or personal casualties. Then, then

2) It is strictly forbidden to splash water, diesel and other corrosive liquids into the liquid crystal screen and the interior of the test table and the electrical connection site.

3) There are precision electronic instruments inside this test table, please do not fall.

4) When using wire beams and plugs, please try to use screws as much as possible to prevent faults from connecting. If the display is flickering or the blue screen, the program is interrupted or the flower screen, please turn off the power and check the external power after checking.

5) When the fuel tank is not added in the fuel tank, it is strictly forbidden to turn on the total power switch to prevent damage to the dry burning of the heater!

6) The pressure can reach 2800BAR at the highest pressure when detecting the co -sprayer in this test table, so the operation room safety door must be closed during the detection room! Intersection Intersection

7) The front of the operating room is strictly prohibited when the first operating room is runtime to prevent the danger from high -voltage leakage. The first time after the device is running after the tested injector is completed, the operator is not allowed to stand in the operating room in the operating room. front! Intersection Intersection

8) If the problem is not improved, please call the company's technical staff, we will serve you wholeheartedly.

3. About Security

In order to ensure safety operations, please follow the following rules:

1) Use independent special sockets and perform reliable grounding. The power cord of this device is 380V of three -phase and five -line line, please make sure it is reliable;

2) If the power supply voltage is unstable, please use the power voltage regulator to supply power;

3) Check regularly whether the AC power cord is good, and whether the power plug or the power socket is accumulated in the dust;

4) If the controller is abnormal, or an abnormal sound or smell is emitted, or the controller is hot until it cannot be touched, please stop using it immediately, and unplug the AC power line plug and all other connectors in the power socket.

5) If the controller fails, please contact the after -sales service personnel to get necessary help.

4. Use And Maintain

1) Please do not throw, fall or step on the control system to avoid the control system from being damaged by strong external force impact;

2) Please do not insert the foreign body into the connector part of the controller;

3) Please do not pour water or other liquids into the internal or controller;

4) Do not touch the AC power line terminal with wet hands;

5) Please do not allow dust or foreign bodies to accumulate around the terminal of the AC power supply. Dust and foreign objects accumulated on the AC electrical terminal may cause fire or cause electric shock;

6) Please unplug the power cord when cleaning the controller.

1. Brief Description

The function of the CR777 co -rail injection device detection table is to imitate the working conditions of the diesel engine ECU (Engine Control Unit). The rail sprayer is done; the driver signal parameter user can set it according to their actual situation and save it to facilitate maintenance personnel to judge and repair the working status of the high -voltage common rail system.

2. The Operating Environment, Conditions, And Specifications Of The Trial Table

Temperature (during operation) ****************** -10~50 ℃ (14~122 ° F)

Temperature (non operating) ********************* -20~70 ℃ (-4~158 ° F)

Relative humidity (during operation) **** 15% to 95% at 40 ℃ (without frost)

Relative humidity (non operating) ******* 90% at 65 ℃ (no frost)

3. Technical Parameters

Host nominal power (KW): 4

Heating pipe power (KW): 1

Overall size (MM): 900x680x1520;

Weight (kg): 220kg

4. Preparation Work

4.1 Checking accessories

Receive the goods to open the box, please check whether the items in the packaging box are consistent with the box. If you lack any items, please contact the after -sales service staff in time.

If the test system is complete and complete, follow the steps below.

4.2 Check the power supply before accessing the power supply. The power line of this device is 380V of three -phase and five -line line, please ensure reliable grounding; if the power supply voltage is unstable, please use the power supply regulator to supply power.

4.3 Pump oil or 0#diesel for injection jet pump for injection pump

5. Function Introduction

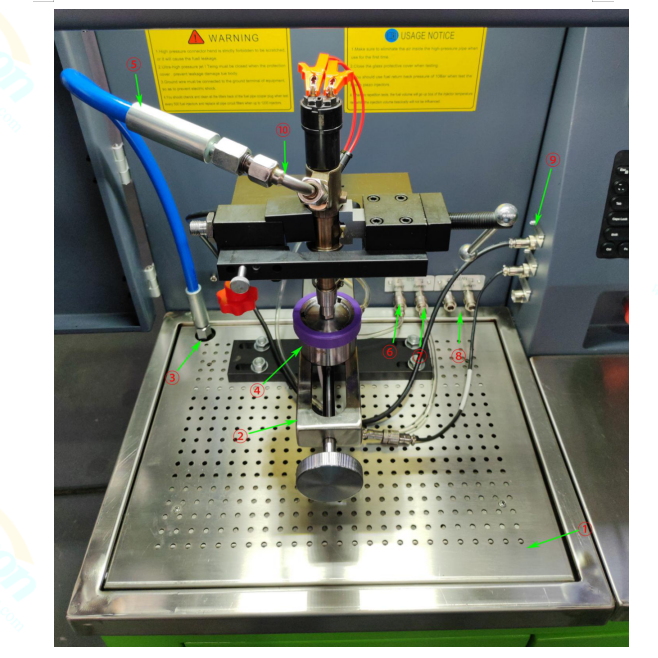

5.1 Operation Room Function Zone

1. Stainless Steel Operation Room 2. Jets bracket

3. High -pressure oil import 4. oil collector

5. High pressure oil pipe 6. Test fuel injection interface

7. Test the oil return interface 8. Injector cleaning interface

9. Multifunctional injector fixture 10. High -pressure oil conversion joint

Note: The 7 -bit cleaning interface is used for testing in the state of not disassembling and cleaning in the injector to prevent unclean test oil from entering the main circulation system. The flow measurement system does not work.

English

English Русский

Русский Español

Español