PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

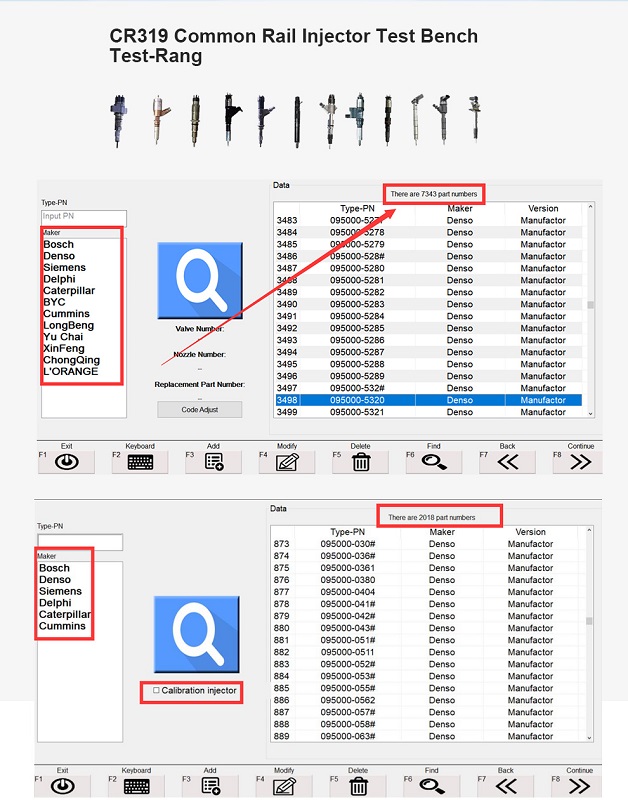

CR319 common rail injector test bench is for BOSCH DENSO DELPHI SIEMENS PIEZO injector test,coding ,with bip injector response time test function.

0086-18253885135

1.Instructions For Using

(1)Before using the CR319 common rail injector test bench, please read this manual carefully

(2)This manual is written based on the existing features and product configurations of the product. If new features and configurations are added, this manual will be modified accordingly. Our company has the right to modify the instruction manual without prior notice to you

(3)Please carefully read the "Precautions" and "Instructions for Use" in the manual to ensure that you can conduct the test safely and correctly

2. Common Rail Fuel Injection Pump Test Bench Protection And Use Precautions

(1)Operators must operate in accordance with the safety regulations of the oil pump repair industry and related diesel electronic control system maintenance. Special attention should be paid to environmental factors such as acid and alkali, toxic gases, high-pressure heavy objects, and items that are prone to sparks, to prevent equipment damage or personal injury

(2)It is strictly prohibited to splash corrosive liquids such as water and diesel onto the LCD screen, the interior of the test bench, and electrical connections

(3)There are precision electronic instruments inside this test bench, please do not drop or touch them

(4)When using wiring harnesses and plugs, please try to use screws to tighten them as much as possible to prevent loose connections from causing malfunctions. If the display screen flashes or is blue, the program is interrupted or the screen is blurred, please turn off the power, check the external power supply, and then restart the machine for testing

(5)It is strictly prohibited to turn on the main power switch when fuel is not added to the fuel tank to prevent damage caused by dry burning of the heater!

(6)When testing the common rail injector on this test bench, the maximum pressure can reach 2500bar, so the safety door of the operating room must be closed during testing!!!

(7)When the test bench is first running, it is strictly prohibited to stand on the front of the operating room to prevent danger caused by high-pressure leakage. During the first startup after each clamping of the tested fuel injector during equipment operation, operators are not allowed to stand on the front of the operating room!!!

(8)If the problem cannot be improved, please call our company's technical personnel, and we will be happy to serve you.

To ensure safe operation, follow each of the following rules:

1) Use an independent dedicated socket and conduct reliable grounding. The power cord of this equipment is three-phase five-wire 380V, please ensure reliable grounding;

2) If the power supply voltage is unstable, please use a power regulator to supply power;

3) Regularly check whether the AC power cord is in good condition, and whether there is dust accumulation on the power plug or power socket;

4) If the controller appears abnormal, or emits an abnormal sound or smell, or the controller is too hot to touch, please stop using it immediately, and unplug the AC power cord and all other connections from the power outlet.

5) If the controller fails, please contact the after-sales service personnel to obtain necessary help.

1) Do not throw, drop or step on the control system to avoid the control system being damaged by strong external force;

2) Do not insert foreign objects into the connector part of the controller;

3) Do not pour water or other liquids into the controller or on the controller;

4) Do not touch the terminals of the AC power cord with wet hands;

5) Do not allow dust or foreign objects to accumulate around the terminals of the AC power supply. Dust and foreign objects accumulated on the AC terminals may cause fire or electric shock;

6) Please unplug the power cord when cleaning the controller.

5.A brief Description Of The Common Rail Injector Test Bench

The function of CR319 common rail injector test bench is to imitate the working condition of the diesel engine ECU, and provide control signals of Bosch, Denso, Delphi, piezoelectric ceramics and other common rail systems to drive the Common rail oil pump and Common rail injector to work; The driving signal parameters can be set and saved by the user according to his own actual situation, so that the maintenance personnel can judge and maintain the working status of the Common rail system.

6.Operating environment, conditions and specifications of the common rail injector test bench

Temperature (running) *************-10~50°C (14~122°F)

Temperature (non-operating)************-20~70°C (-4~158°F)

Relative humidity (running) ********* 15%~95% at 40 ℃ (no frost)

Relative humidity (non-operating) ****** 90% at 65 ℃ (no frost)

7.Technical Parameters

Host nominal power (kW): 4

Heating tube power (kW): 1

Rated power of circulating pump (kW): 0.18

Overall size (mm): 1500x1000x1520;

Weight (KG): 390

8. Preparation Work

(1)Check accessories

Upon receiving the goods and opening the packaging box, please immediately check if the items inside the packaging box match the packing list. If any items are missing, please contact after-sales service personnel in a timely manner

If the testing system is in good condition and the accessories are complete, follow the steps below

(2) Check the input power supply of the device before connecting to the power supply. The power line of this equipment is three-phase five wire 380V, please ensure reliable grounding; If the power supply voltage is unstable, please use a power regulator for power supply

(3)Fill the fuel injection pump with dedicated test pump oil or 0 # diesel fuel

9. Function Introduction

(1)Introduction to the Ribbon

1. Control panel 2 Mouse and keyboard functional area

3 Operation room 4 Emergency stop control button

5. Heating indicator light 6 Cooling indicator light (fuel tank cooling)

7 Power indicator light

1. High pressure fuel supply pipe

2 Fuel injector power cord

3 Piezoelectric injector power cord

4. Response time sensor power cord

5 Multifunctional fuel injector fixture

6 Fuel injector injection measurement interface

7. Fuel injector return measurement interface

8 Fuel injector injection cleaning interface

9. Fuel injector return cleaning interface

Attention: The interfaces 8 and 9 are used for testing when the fuel injector is not disassembled and cleaned, to prevent unclean test oil from entering the main circulation system. When the fuel injection and return of the fuel injector are connected to this interface, the flow measurement system of the test bench does not work.

SUPPORT CUSTOMIZE DIFFERENT COLOR:

--

WITH TOP QUALITY INJECTOR COUPLING:

WITH NEWEST COMMON RAIL TEST SYSTEM

ACCESSORIES:

English

English Русский

Русский Español

Español