Company news,Industry news & FAQ

NEWS

PRODUCTS SEARCH

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

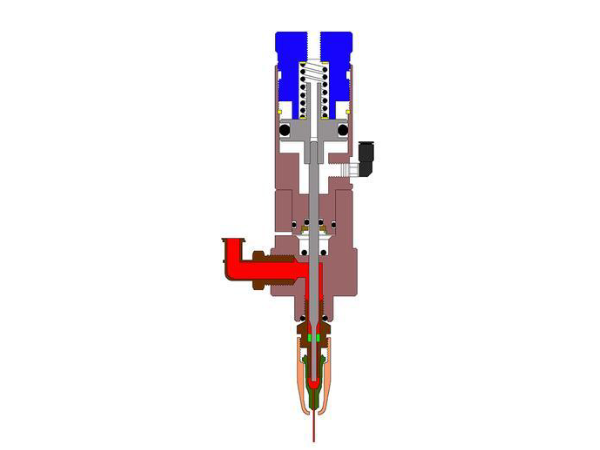

Injector, this high-precision and precise device, its core components include needle valve and needle valve body, which have extremely high precision. The main task of the fuel injector is to accurately control the injection amount of fuel based on the injection pulse signal sent by the ECU.

In the market, fuel injectors can be roughly divided into four types: axial needle electromagnetic fuel injectors, ball valve electromagnetic fuel injectors, plate valve electromagnetic fuel injectors, and lower inlet fuel injectors.

The causes of fuel injector failures are often related to dirt in diesel engines, mainly because the injector head works in a high-temperature and high-pressure combustion chamber environment for a long time. Due to the effects of thermal expansion and contraction, the needle valve may gradually expand and deform, or the fuel injection port may be blocked by carbon deposits, resulting in a decrease in fuel injection volume and thus affecting the normal operation of the diesel engine.

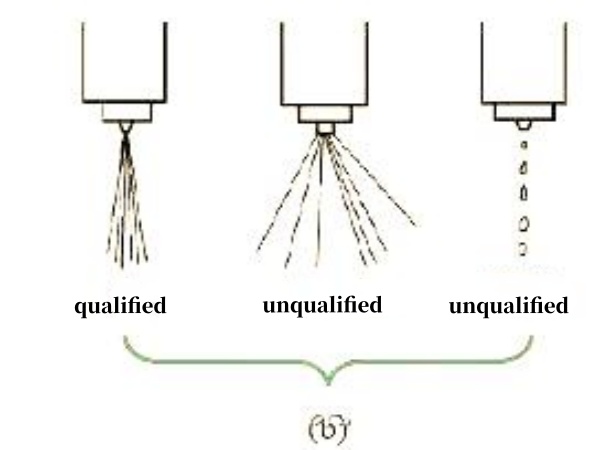

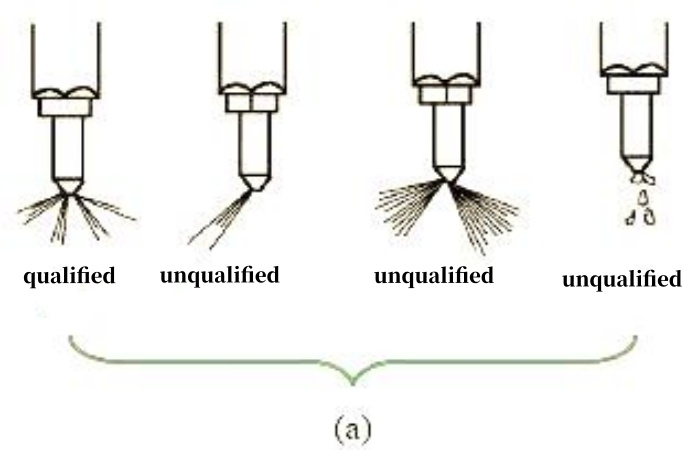

There are various reasons for poor atomization of fuel injectors, including insufficient fuel injection pressure, carbon deposition due to nozzle wear, worn or weakened spring end face, etc. These factors can cause the fuel injector to open prematurely and close slowly, resulting in poor fuel atomization. For single cylinder diesel engines, this will result in their inability to operate, while for multi cylinder diesel engines, problems such as power loss, black smoke emissions from the exhaust, and abnormal machine operation may occur.

In addition, damage to the fuel injector return pipe is also a common problem. When the needle valve components are severely worn or the needle valve body is not tightly matched with the injector housing, the return oil volume will significantly increase, even reaching 0.1-0.3 kg/h. If the return oil pipe is damaged or not installed, the return oil will be lost in vain, causing waste. Therefore, it is necessary to ensure that the return pipe is intact and installed in a sealed manner, so that the return oil can flow smoothly into the tank. If the return pipe is connected to the diesel filter, a one-way valve should be installed at its terminal to prevent the diesel inside the filter from flowing back to the injector.

In addition, the enlargement of the needle valve nozzle is also a noteworthy issue. Due to the continuous jet erosion of high-pressure oil flow, the needle valve nozzle will gradually wear and expand, resulting in a decrease in injection pressure, shortened injection distance, poor diesel atomization, and increased carbon deposition in the cylinder. For single hole axial needle fuel injectors, a steel ball with a diameter of 4-5 mm can be placed at the end of the hole and gently tapped with a hammer to cause plastic deformation and reduce the aperture. For multi hole direct injection injectors, due to the large number of holes and small aperture, only high-speed steel ground samples can be gently tapped at the hole ends. If the debugging still fails, the needle valve components should be replaced

On the other hand, needle valve biting is also an issue that cannot be ignored. The moisture or acidic substances in diesel may cause the needle valve to rust and get stuck, and after the sealing cone of the needle valve is damaged, the combustible gas in the cylinder will enter the mating surface and form carbon deposits, further causing the needle valve to bite and lose its fuel injection function. The solution to this problem is to place the needle valve assembly in waste engine oil and heat it until boiling and smoking, then remove it. Use pliers with a soft cloth to clamp the tail of the needle valve and slowly move it to remove it from the clean engine oil and repeatedly grind it

The last thing to pay attention to is the end face wear of the needle valve body. This may be due to the inevitable wear phenomenon caused by the high temperature and high pressure environment inside the cylinder. However, this wear and tear can affect the normal operation of the fuel injector, so regular inspection and maintenance are needed to ensure its continuous and stable fuel injection function. The end face of the needle valve body is frequently impacted by the reciprocating motion of the needle valve, which may form pits over time, thereby increasing the needle valve lift and interfering with the normal operation of the fuel injector. For this, the needle valve body can be placed on a grinder, its end face can be ground and repaired, and fine grinding paste can be used to finely grind it on a glass plate

In addition, the problem of air leakage and oil leakage between the fuel injector and the cylinder head joint hole cannot be ignored. When installing the fuel injector, it is necessary to thoroughly remove the carbon deposits in the installation holes and ensure the flatness of the copper gasket. Avoid using asbestos board or other materials as substitutes to prevent poor heat dissipation or sealing failure. If self-made copper gaskets are required, they should be processed according to the specified thickness of copper to ensure that the distance of the fuel injector protruding from the cylinder head plane meets the technical requirements. For example, for 135 series diesel engines, this distance should be controlled within the range of 1.5-2 mm. In addition, the concave shape of the fuel injector pressure plate should be installed downwards, and uniform torque should be applied during fastening to avoid unilateral bias causing deformation and deviation of the fuel injector head, which can lead to air leakage and oil leakage

The wear of the needle valve and the guide surface of the needle valve hole is also a concern. Due to the frequent reciprocating motion of the needle valve in the needle valve hole and the invasion of impurities and dirt in diesel, the guide surface of the needle valve hole may gradually wear, the gap may increase, or scratches may appear. This will lead to an increase in fuel injector leakage, a decrease in pressure, a reduction in fuel injection quantity, and a time lag, which in turn will affect the starting of the diesel engine. At this point, it should be considered to replace the needle valve components to solve the problem.

In addition, the issue of fuel injector dripping cannot be ignored. When the fuel injector is working, the sealing cone surface of the needle valve body will be subjected to frequent strong impacts and high-pressure oil flow injection, which may cause scratches or spots on the cone surface and loss of sealing. This will cause the diesel engine to emit white smoke from the exhaust pipe at low temperatures, turn into black smoke at high temperatures, and emit irregular blasting sounds. At this point, you can try disassembling the fuel injector, grinding and cleaning the cone surface, and then reinstalling it for testing. If it is still not qualified, the needle valve assembly needs to be replaced

English

English Русский

Русский Español

Español