PRODUCTS SEARCH

Products

CONTACT US

Tel: 0086-18253885135

Fax: 0086-538-3318184

Address: High Tech Industry Zone of East Tai an city,Shandong Province,China

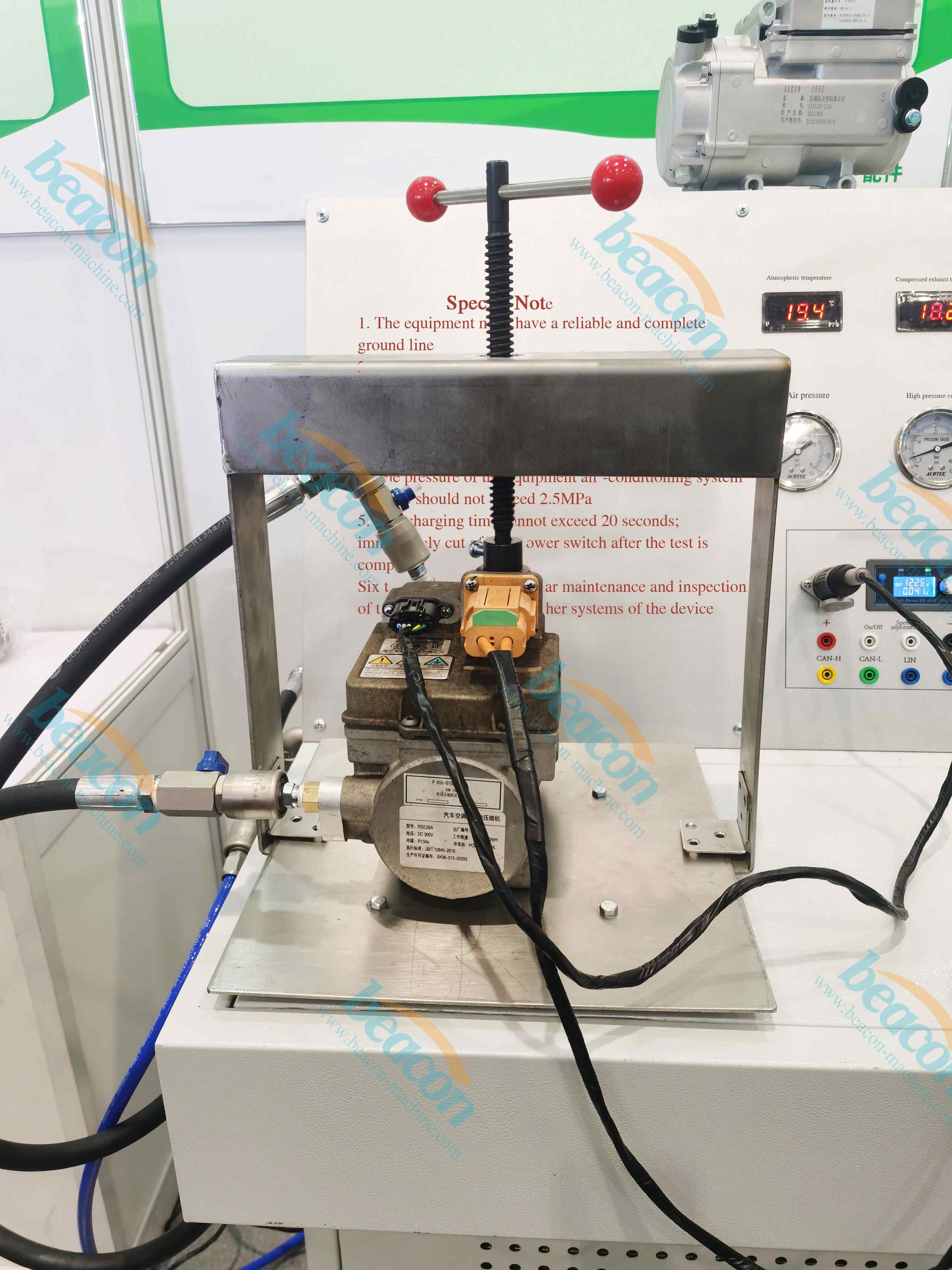

New Energy Electric Car Air Conditioner Compressor Composite Performance test bench NC101

0086-18253885135

Function Introduction:

(1)One channel of DC 0 ~ 650V/30A output

(2)One channel of DC 0~30V/25A output

(3)There are two levels of pre -charging functions.

(4)There is a self -discharge function after power off.

(5)There are 5Mn insulation testing

(6)There is an AC/DC leakage and overload protection function

(7)"Air" test mode: have electrical control over pressure (8KG) protection function and mechanical ultra -pressure (10kg); there is electric exhaust and manual oil discharge function

(8)"Air Conditioning" test mode: It has its own air -conditioning system to draw real vacancy/air -conditioning system refrigerant recycling function; there is a high/low voltage protection function of the electronic control air -conditioning system

(9)Adjustment of compressor speed;

(10)There are commonly used compressors to enable/CAN/LIM startup ports; when external special drives or computers, they can meet all compressor detection in the market.

(11)Because one machine has two test modes: "air"+air conditioning ", it can quickly judge the basic performance of the compressor;It can also truly simulate the use of the compressor in the air conditioning system; it can quickly/intuitive detection of various parameters of the compressor

(12)Equipment comes with work -controlled man -machine exchange, preset commonly used test drivers, high degree of automation. (This software function is under development)

(13) Suitable for compressor maintenance detection and compressor parts and assembly production enterprises, durability testing

English

English Русский

Русский Español

Español